Öffnet in neuem Fenster

Opens in a new window

Öffnet externe Seite

Opens an external site

Öffnet externe Seite in neuem Fenster

Opens an external site in a new window

PVcomB

Key Equipment

Our group operates a variety of state-of-the-art deposition, structuring and characterisation instruments that are used for research and development of catalyst materials, microsystems and reactors.

A unique feature of the deposition tool is that they offer a sample transfer to the synchrotron and lab based analytics infrastructure availabe at the EMIL corelab of HZB. Access to our facilites can be arranged based on research collaborations or on cost basis.

Deposition / Sample Preparation

Oxford Instruments PlasmaPro100 (PECVD, RIE, D-RIE)

For selected material deposition, surface preparation/etching as well as microstructuring, an Oxford Instruments PlasmaPro 100 cluster offers the following technologies

- high-temperature (PE)CVD "nanofab" for SiOx, SiNx, SiCx, a-Si/nc-Si, carbon modifications including vapour delivery module for liquid precursurs & mixed-frequency (RF/LF) operation

- PlasmaPro 100 Estrelas deep reactive ion etcher for 3D structuring, Bosch(r), mixed-gas and cryogenic high-rate/high selectivity etching based on fluorine chemnistry

- Parallel plate RIE chamber for etching / surface treatments using oxygen, fluorine or chlorine chemnistry

Beneq TFS200 ALD

- Atomic Layer Deposition processes for Al2O3, TiO2, Co(O), SiO2

- pure thermal or plasma assisted processes possible

- option for process control (rate measurements, spectroscopic ellipsometry)

- availabe oxidators: water or ozone

- UHV transfer port for substrates up to 8-inch

Prevac confocal sputter system

- Co-sputter system with 8 sources (2-inch targets)

- Deposition of metals, alloys and mixed alloys/oxides

- sputter-up configuration with DC/RF excitation

- sample heater up to 700°C on 50x50mm²

- fully integrated into the EMIL analytics

Von Ardenne CS400 (PVD, PECVD)

Mid-temperature PECVD/PVD cluster system

- PECVD a-Si(i/n/p):H, SiOx,

- high rate electron beam evaporator (up to 1000nm/min)

- plasma RTP annealing chamber

Analytics (finalised Q3/2025)

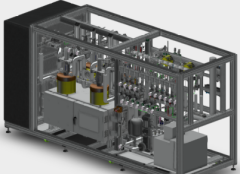

ILS parallel reactor

For catalyst characterisation and chemical process development, an Integrated Lab Solutions (ILS) parallel reactor will be available mid 2025 comprised of:

- Parallel reactor for R&D on syngas and fuel generation, Dry reforming, RWGS and others

- Two skids with 4 CSTR (Berty-Tyoe) reactors each - fully automated and online analytics. High-temperature/Low-pressure unit up to 800°C and 5Bar, High-pressure/Low-temperature unit up to 100 Bar and 500°C

FTS reactor development platform

For evaulation of new thin-film reactor concepts a development platform will be available april 2025

- Micromeritics FR100 base unit with exchangeable reactor tube

- customised for Fischer-Tropsch processes

- flexible analytics (μGC, GC, MS)

Mini reactor for CO2 hydrogenation

- Parr series 4566HT mini reactor for CO2 hydrogenation

- Maximum operation conditions: 400°C / 120Bar

- Custom built sample holder for thin-film catalyst plates

- flexible analytics